- Home

- Products

- Heavy Duty Plastic Scrap Grinder Machine

- Injection Molding Plastic Shredder

- Plastic Recycling Shredder

Plastic Recycling Shredder

Application

Plastic recycling shredder is used to recovery and reuse all kinds of plastic material after being crushed, including plastic wastes, leftover materials, degraded materials and some other disqualified materials. Plastic recycling shredder also fits for ABS, PVC, PA, PE, PC, PU and some other kinds of soft or hard plate plastic, dendritic plastic and mesh plastic. These plastic crush will be reused by mixing with raw materials in proportion after they are recovered by recovery system.

Features recovery system

Plastic recycling shredder is equipped with recovery systems which can recover and reuse degraded materials produced by injection molding machines. This process doesn't need manual work. All of these can reduce the cost.

Our plastic recycling shredder can recover the degraded materials produced by injection molding machines in 30s without waiting for the stacking of the degraded materials. It can improve the efficiency of the injection molding machines and can make the environment cleaner.

Features of structures

1. Plastic recycling shredder adopts stainless steel feeding hoppers which has good rust resistance and is convenient to be cleaned.

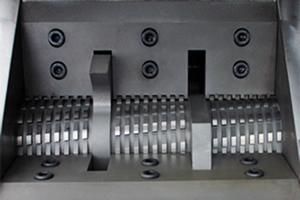

2. The cutters of plastic recycling shredder are made of Cr12MVo (cold work die steel). SKD-11 can also be selected. The cutters of these materials have a good wear resistance and a longer service life.

3. The gear cutter can directly crush the plastic without screens.

4. It is convenient to disassemble the equipment, change the colors or raw materials and clean the devices.

5. Plastic recycling shredder is suitable in narrow space because of its tiny size and weight.

6. It is convenient to be removed with the wheels in the bottom of the equipment

Features of performance

The speed of the plastic recycling shredder is 29r/min. So it can make lower noise with the slower speed. It is equipped with protection systems like motor overload protection system, power interlock protection system, security switches and so on. It also has alarm systems. All of these systems make it safer to operate the equipment.

| Motor/Power | Crushing Capacity KG/H |

Feeding Inlet Size (MM) |

Speed r/min | Blade Quantity | Weight (kg) | Machine Size (MM) |

Fun Power |

| 2HP/1.5KW | 12-20 | 250*220 | ∅190-∅100 | 29 | 166 | 990*470*1055 | 550W/250W |

| Motor/Power | Crushing Capacity KG/H |

Feeding Inlet Size (MM) |

Speed r/min | Blade Quantity | Weight (kg) | Machine Size (MM) |

Fun Power |

| 3HP/2.2KW | 18-30 | 320*240 | ∅212-∅100 | 36 | 220 | 1095*470*1155 | 550W/250W |

| Motor/Power | Crushing Capacity KG/H |

Feeding Inlet Size (MM) |

Speed r/min | Blade Quantity | Weight (kg) | Machine Size (MM) |

Fun Power |

| 3HP/2.2KW | 20-50 | 430*330 | ∅300-∅100 | 36 | 350 | 1180*470*1130 | 550W/250W |

| Motor/Power | Crushing Capacity KG/H |

Feeding Inlet Size (MM) |

Speed r/min | Blade Quantity | Weight (kg) | Machine Size (MM) |

Fun Power |

| 5HP/4KW | 30-80 | 560*410 | ∅363-∅150 | 29 | 550 | 1500*700*1755 | 550W/250W |

Please select the suitable standard voltage according to different national voltage requirements of different countries.

Customers can order nonstandard equipment. For instance, the feeding inlet can be equipped with slides, hopers and super magnet.

Plastic recycling shredder can be equipped with proportional valves for two kinds of material which can help to feed the material.

Configurations

Electromechanical part: Shengbang Motor (the tertiary energy consumption), Schneider Electric (Devices of assigned brands can be installed).

The brand of the bearing is KOYO.